Latest News

Case Hardening on a Linear Shaft

Feb 27, 2024

What is Case Hardening?

Case hardening is a heat treatment process used to selectively harden the surface of a metal, usually low-carbon steel. The goal is to create a part with the following qualities:

- Hard, wear-resistant surface: This outer layer offers superior resistance to scratches, abrasion, denting, and fatigue caused by repetitive stress.

- Tough, ductile core: The inner core maintains higher ductility and toughness, providing the part with the ability to absorb impacts and resist deformation without breaking.

Benefits of Case Hardening

- Enhanced Wear Resistance: The hardened surface dramatically improves resistance to abrasion, scratches, and indentation.

- Improved Fatigue Strength: Case hardening helps prevent cracks from forming and propagating under repetitive stress and loads, extending the part's lifespan.

- Maintains Core Toughness: Unlike through hardening, the core remains relatively soft, providing shock resistance and preventing catastrophic brittle fractures.

- Cost-Effective: It's often more cost-efficient to case harden a low-carbon, less expensive steel than to use a high-carbon steel for the entire component.

Machining Considerations

- Hardened outer surface will increase tool wear on O.D. Turning operations such as parting, grooving, facing.

- Recommend use of specialised turning inserts (e.g. CBN Tipped inserts)

- Suitable for griding operations (e.g. Cut-Off wheel, surface grinding flat features)

- Ductile core allows end drilling & tapping without the need for specialised tooling.

Enclosure Door Design for Tight Spaces

Dec 19, 2023

How can we effectively enclose equipment, while retaining easy access for operations and maintenance?

What style of doors can we use to tackle these challenges?

Which door design is space saving?

Swing Doors

| + Lowest Cost Option |

|

| + Single Hand operation | |

| - Requires largest clearance Space |

Slide & Fold Doors

| + Require only half clearance space |

|

| Two Hand operation |

Sliding Doors

|

+ Zero forward clearance space required |

|

|

- Obstructs access space (depend on # of panels) |

Lifting Doors

|

+ Zero forward clearance space required |

|

|

- Requires equivalent clearance above enclosure |

Linear Shaft vs Linear Rails

Dec 7, 2023

Both linear shafts and linear rails are used for linear motion, but there are some key differences between them:

Linear shafts:

- Simple design: A round shaft made of steel, stainless steel, or hardened chrome.

- Lower cost: Generally cheaper than linear rails.

- Easy to install: Can be supported by bearings or bushings.

- Less accurate: Can bend or deflect under load, leading to less precise motion.

- Lower load capacity: Not suitable for high-load applications.

- Higher friction: Requires more lubrication than linear rails.

- Limited self-alignment: Can twist or rotate under load, requiring additional components to prevent it.

Linear rails:

- More complex design: Consists of a hardened steel rail with rolling elements like ball bearings or rollers.

- Higher cost: More expensive than linear shafts.

- More difficult to install: Requires precise alignment and mounting.

- More accurate: Offers more precise and consistent motion due to its rigid design.

- Higher load capacity: Can handle heavier loads than linear shafts.

- Lower friction: Requires less lubrication than linear shafts.

- Self-aligning: Some types of linear rails can self-align, compensating for minor misalignment.

Key differences:

Choosing between linear shafts and linear rails:

The best choice for your application will depend on several factors, including:

- Required level of accuracy and precision

- Expected load

- Budget

- Complexity of installation

- Need for self-alignment

Here are some general guidelines:

-

Use linear shafts for:

- Low-cost applications

- Simple designs

- Light loads

- Non-critical applications where high accuracy is not required

-

Use linear rails for:

- High-precision applications

- Heavy loads

- Complex designs

- Applications requiring self-alignment

Here are some additional resources that you may find helpful:

- Linear rails vs. linear rods – which are better? https://www.matara.com/technical-articles/linear-rail-faqs/

- Round shaft or profiled rail for linear motion? How to choose https://www.linearmotiontips.com/round-shaft-or-profiled-rail-how-to-choose/

- Linear Ways vs Linear Rails vs Linear Rods (Im searched out and still lost) https://www.cnczone.com/forums/linear-and-rotary-motion/167612-cnc.html

Lean Pipe and Joint System

Dec 7, 2023

Lean pipe and joint systems offer numerous advantages for various industries, including manufacturing, warehousing, retail, and logistics.

Key benefits:

Flexibility:

- Easy to assemble and reconfigure without welding or special tools

- Modular design allows for quick adjustments and modifications to meet changing needs

- Can be easily adapted to different layouts and spaces

- Ideal for dynamic environments where processes and workflows frequently evolve

- Compatible with many existing structures and racking systems

Cost-effectiveness:

- Relatively inexpensive materials and components compared to traditional welded structures

- Reduced installation and maintenance costs due to simplicity

- Scalable solutions can be built to accommodate growth without significant investment

- Minimized waste through reuse and repurposing of components

Improved efficiency:

- Streamlined material flow and reduced travel distances due to customizable layouts

- Optimized workspaces for better ergonomics and productivity

- Enhanced organization and visual management of materials and tools

- Reduced setup times for production changes

Safety:

- Smoother surfaces and rounded edges minimize the risk of injuries

- Lightweight components are easier to handle and maneuver

- Ergonomically designed workstations help prevent musculoskeletal disorders

Sustainability:

- Durable and long-lasting materials require minimal replacement

- Many components are recyclable, contributing to a closed-loop system

- Lean principles promote waste reduction and resource optimization

Additional advantages:

- Improved working environment: Clean and organized workspace promotes employee satisfaction

- Increased visibility and communication: Open design facilitates collaboration and problem-solving

- Enhanced quality control: Standardized processes minimize errors and improve consistency

-

Easy cleaning and maintenance: Smooth surfaces facilitate cleaning and sanitation

Here are some specific examples of how lean pipe and joint systems are used to improve efficiency and productivity:

- Assembly lines: Create customized workstations with adjustable heights and angles for improved ergonomics

- Inventory management: Build flow racks and storage systems for efficient product organization and retrieval

- Material handling: Design carts and trolleys for optimized material flow throughout the facility

- Workbenches: Build adjustable workbenches with storage shelves and tool holders for improved ergonomics and efficiency

- Retail displays: Create flexible and modular displays that can be easily adapted to different products and promotions

Lean pipe and joint systems offer a versatile and cost-effective solution for improving productivity, efficiency, and safety in any industry.

Adopt Wheeler Mectrade's Aluminum Pipe & Joint system today!

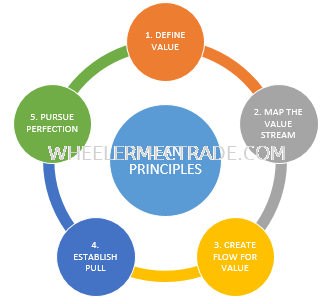

Lean Methodology and your Workplace

Dec 6, 2023

What is ''Lean Methodology''?

Lean methodology is a business management system that aims to eliminate waste, improve efficiency, and create value for customers. It is based on the following five principles:- Identify value: Define what value is from the customer's perspective.

- Map the value stream: Identify all the steps in the process that creates and delivers value to the customer.

- Create flow: Make the process flow as smoothly as possible by eliminating bottlenecks and non-value-adding activities.

- Establish pull: Don't produce anything unless the customer actually needs it.

- Seek perfection: Continuously strive for improvement by regularly identifying and eliminating waste.

- 5S: A workplace organization method that involves sorting, setting in order, shining, standardizing, and sustaining.

- Kanban: A system for managing the flow of work through a process.

- Kaizen: A Japanese philosophy of continuous improvement.

- Poka-yoke: A system for preventing mistakes.

- Reduce costs: By eliminating waste and improving efficiency.

- Improve quality: By identifying and preventing defects.

- Increase customer satisfaction: By delivering products and services that meet or exceed customer expectations.

- Shorten lead times: By making processes more efficient.

- Increase employee engagement: By involving employess to improve their work environment.

How can we help?

- Standardization and flexibility: Modular aluminum profile systems are based on a standardized set of components, which can be easily assembled and disassembled to create a wide variety of structures and configurations. This standardization makes it easy to implement lean principles such as 5S and Kanban, as it reduces the number of different parts that need to be managed and stored.

- Quick changeover and adaptability: Modular aluminum profile systems can be quickly and easily changed over to accommodate new products or processes. This adaptability makes it possible to implement lean principles such as pull and seek perfection, as it allows organizations to respond quickly to changes in customer demand and market conditions.

- Waste reduction and efficiency: Modular aluminum profile systems are designed to be lightweight and easy to handle, which can help to reduce waste and improve efficiency. This is because they require less material and labor to transport, assemble, and disassemble than traditional construction methods.

- Visual management and error prevention: Modular aluminum profile systems can be used to create clear and visual representations of work processes through jigs and fixtures, which can help to improve communication and collaboration. This visual management can also help to identify and prevent errors, which is a key principle of the lean methodology.

- Continuous improvement: Modular aluminum profile systems can be continuously improved by adding new components or refining existing ones. This continuous improvement process is essential for implementing the lean methodology, as it allows organizations to identify and correct issues.

-

Assembly workstations: Modular aluminum profile systems can be used to create assembly workstations that are tailored to the specific needs of each task. This can help to improve efficiency and reduce errors by providing workers with the tools and equipment they need within easy reach.

-

Material handling systems: Modular aluminum profile systems can be used to create material handling systems that are flexible and scalable. This can help to reduce waste and improve efficiency by ensuring that materials are always available where they are needed.

.jpeg)

Custom 3D Print to Clone OEM Part

Nov 24, 2023

Unable to source for a 1pc replacement part, we helped our customer to design and clone an OEM conveyor belt side-guide holder.

RFQ to Usable part in less than 3 days!

In-House Turning Services

Nov 7, 2023

Wheeler Mectrade now provides expedited in-house shaft turning services for purchases of Kawada Linear Shafts

Why choose us?

- Stock Shafts ready stock (SUJ2, SUS440C)

- Short lead time for standard turning services (End-tap)

Services:

Facing

Chamfering

End-Drill

End-Tap

SPECIAL OFFER - LMH25LUU

Nov 3, 2023

Special Offer! Discounted LMH25LUU

Limited run clearance of LMH25LUU-42W @ S$30/pc (exGST)

All stock must go, enquire directly for further volume discounts!

Phone: 65638501

Email: wheelermectrade@singnet.com.sg

Note: Flange width of 42mm, all other specifications identical to LMH25LUU

Offer valid while stocks last

Portable Partition

Oct 3, 2023

Free-standing Portable Partition

Lightweight and easy to reposition

Why you should choose Aluminum Profile Extrusions for your next Engineering Project

Jul 17, 2023

Castor Wheel 3D Models

Sep 29, 2022

3D Models for our line of standard Castor Wheels are now available.

3D CAD Models

RoHS Compliance

Sep 21, 2022

View the reports here

Collaborative Robotics (CoBots): The Future of Product Assembly

Sep 20, 2022

Collaborative Robots (CoBots) are making their way into businesses everywhere. Designed to share a workspace with humans, CoBots are the perfect way to help your production line reach higher performance milestones.

Our sturdy Aluminum Extrusion tables and workbenches are fully modular and configurable, ready to adapt your unique needs.

A rigid frame provides the perfect mounting point for your vendor's CoBot mounting plate and control box.

Consult our sales staff to find out more!

Note: Customisation will be required depending on your CoBot make and model

Components for design and assembly of custom 3D printers

Dec 28, 2021We understand that every printer is different. Enjoy full control of your component design though our value-added cut-to-length and machining services.

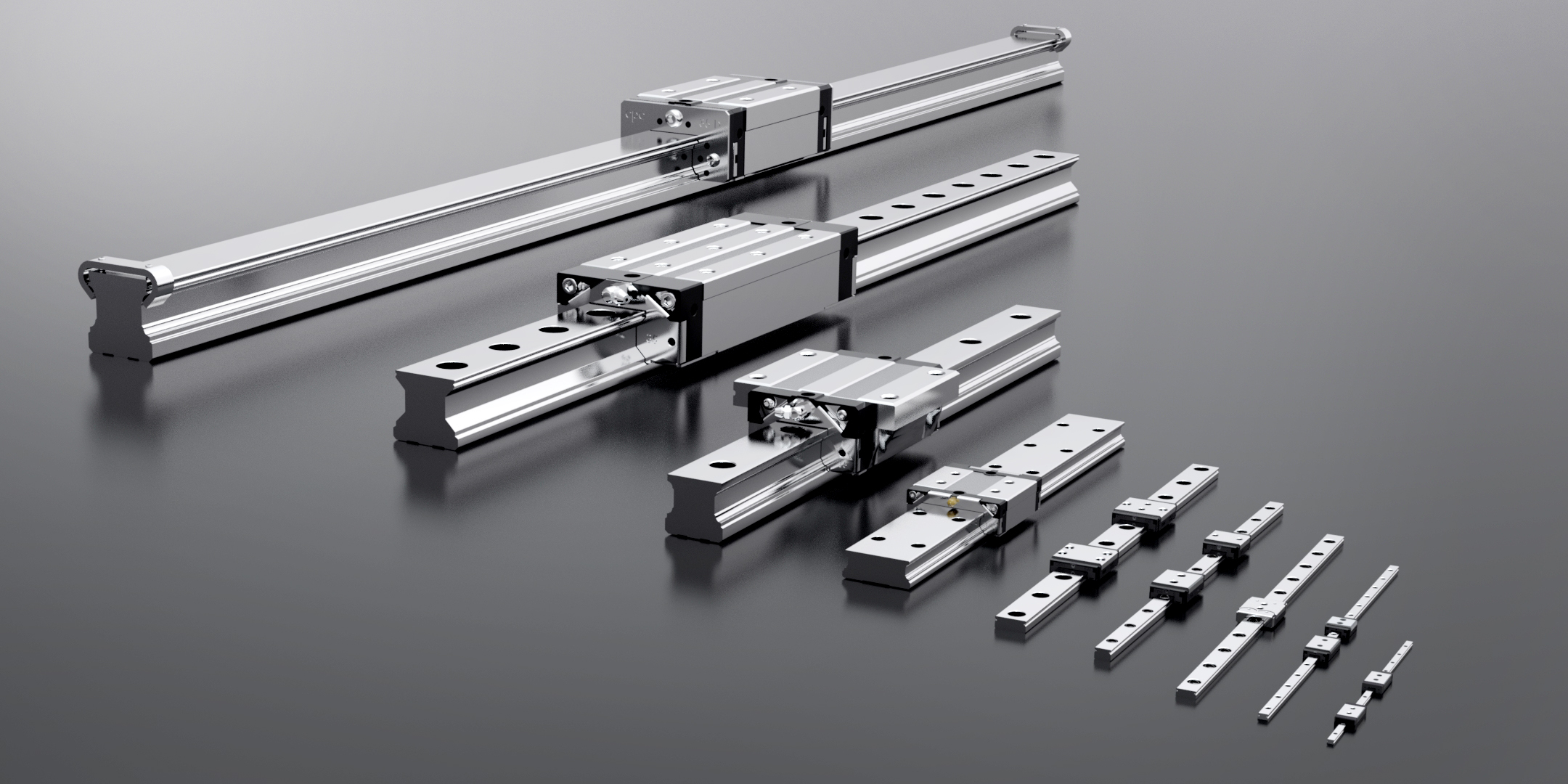

Precision Linear Guides

Linear Bushings

.jpg)

Lead Screws

Shaft Couplings

Timing Belts & Pulleys

Kawada Linear Bushing Lubrication Guide

Oct 2, 2021Lubrication

Kawada Linear Bushings require grease or oil as lubricant for optimal operation.

Our Linear Bushings come pre-lubricated from the factory. However, you may choose to apply additional/replacement lubrication as required.This document will cover the basic principles of Linear Bushing lubrication.

Grease Lubrication

Before mounting the product onto the LM shaft, apply grease to each row of balls inside the Guide Ball Bushing.

Thereafter apply grease as necessary, in accordance with usage and other conditions as required,

if housing with grease nipple & channel are present as shown in Fig.1, apply grease with a grease gun,

or apply grease directly to the LM shaft, after cleaning the shaft of any debris.

We recommend using high-quality lithium-soap group grease No. 2. (aka NLGI Grade 2 Grease)

Oil Lubrication

To lubricate, apply lubricant to the LM shaft one drop at a time, as needed, or through housing with grease nipple & channel

as shown in Fig.1 , in the same manner as when lubricating with grease.

Commonly used lubricants include turbine oil, machine oil, and spindle oil.

Grease Consistency

The most commonly used greases, such as those used in automotive bearings, would use a lubricant that is NLGI grade 2,

which has the stiffness of peanut butter.

Grades within this range can operate in a higher temperature range and at higher speeds than NLGI grades 000-0.

Greases for bearings are typically NLGI grade 1,2, or 3.

Lean Assembly Workbench

Jun 28, 2021

Key Features:

-

Overhead Work Lamp

-

Tilting Parts storage Tray

-

Ergonomic Height Adjust Feet

-

Overhead Tool holders

Create efficient work cells where all parts & tools required are within easy reach.

Proven to improve worker efficiency, reduce product assembly time.

Fold Away Doors

Jun 28, 2021